Humans and technology work together.

Since the first outbreak in December 2019, millions of lives have fallen under the severe destruction of Covid-19. It has disrupted plans, shifted priorities, scrambled existing networks, and made us all acutely aware of the fact that we cannot predict the future.

Humans and technology work together.

But looking on the bright side, the global pandemic is a boost to human’s awareness of their own life quality; meanwhile being a motivation to develop pioneering products, including gloves, that help reduce threats and keeping people safe.

We deliver products that are rooted in science and endorsed by professionals.

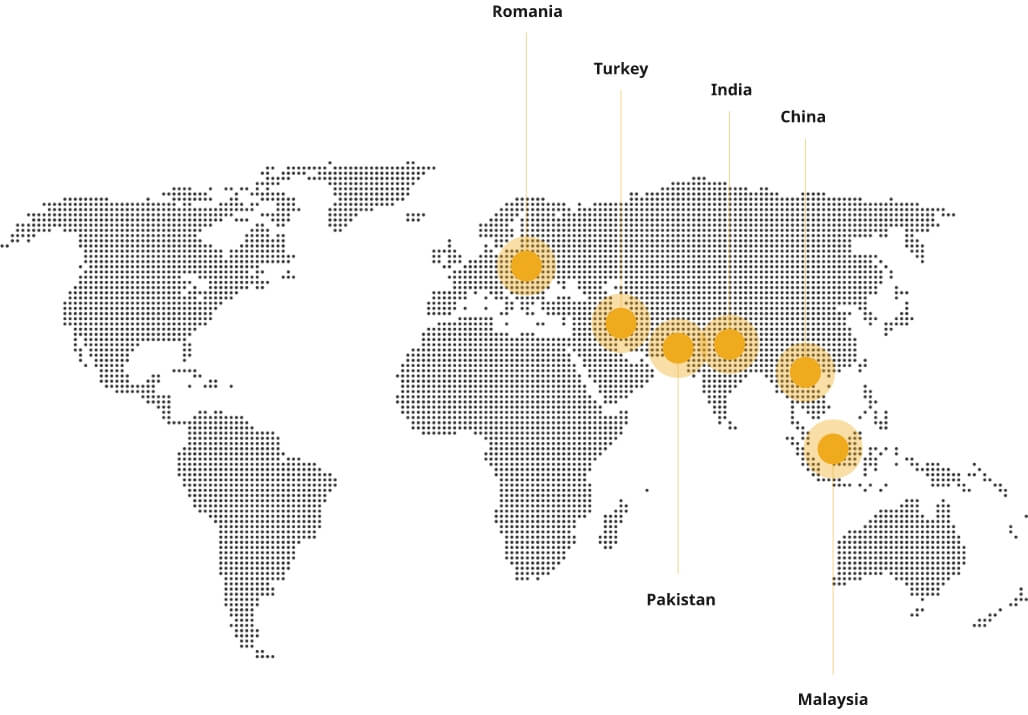

The first few months of the pandemic exposed the fragility of the global supply chain on which the medical supply industry has come to rely on, and presented scammers with the perfect opportunity: the growing and urgent need for protective equipment all over the world. Gloves, gowns, masks were all essential products in high demand by the people in the front line.

In a market dominated by fraud at every corner, we’ve created a new and trustworthy glove brand from scratch. The continuous improvement of work processes was mandatory for our collaborations.

0 risks

We trusted the system to be functioning and accountable. Using everyone’s brainpower to drill it down perfectly, we worked as a team and proceeded each aspect of the process in order to minimize the risks.

This system helps us moving forward and going as far as we possibly can. It allows us to work more efficiently, smarter, and strategically.

boxes delivered between 2020 and 2021

boxes per month (glove production capacity)

2020 turnover

per month (medical gown production capacity)

2021 turnover

deposit has been paid to secure a contract with the manufacturer and 32 production lines